Though I'm considering it I don't have a motorized stage, so I'm not an expert! These are the basics though I've picked up so far:

There are two obvious main ways to go.

A) Move the camera/lens. (I've only seen anyone move camera and lens together, rather than just one, though that would be possible.) One advantage of this approach is that the lighting doesn't move, through the stack. Though microscope focus blocks can be used, a good solution is something like the Proxxon milling table - as first mentioned by Betty planapo!

http://www.proxxon-direct.com/acatalog/ ... _kt70.html (1mm/rev)

B) Move the subject. Though this could be done using other mechanisms, adjustment of the focus on a microscope is an elegant method. (Typ 0.2mm/rev) This is used by Saphicon with their rather neat stepper units.

http://www.saphicon.com/focus-drive-integrated-s.htm (Approx $1300)

As far as I can see, at the extremes, method A) is more suited to lowest magnifications, and B) highest, though there's considerable overlap. Surely the best place for a microscope focus block, from the point of view of rigidity, is on a microscope?

The amount of fine-focus travel is very important to prevent the need to "back-up" the coarse focus mechanism. Some microscopes' fine focus travel is only 150 micrometer(micron), though common Olympus ones are 30mm, and some (which?) Nikon ones approx 70mm.

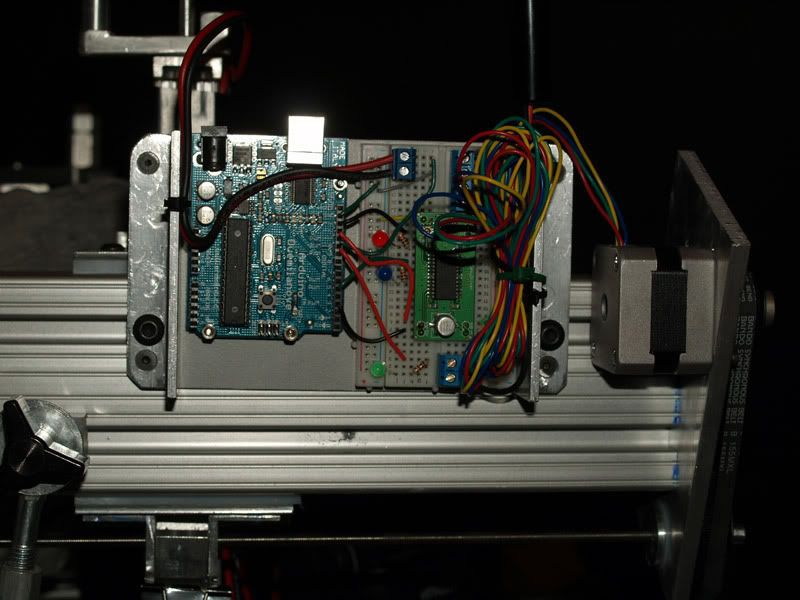

Once you have your motorized mechanism, you have to control it. The most obvious way is to use a microcontroller or PC. If you've never done programming at all, that's a steep learning curve.

As something to play with, I bought a stage and motor s/h for $50. To my surprise it has a 6:1 gearbox between the motor and stage drive, so on a 0.5mm leadscrew gives 26nm per 1/16th microstep. A lot of steps to cover its 50mm, I wonder how it'll behave. Time, energy and metalwork I can't currently do, come between me and its use.

(The vendor may have more, if interested, let me know).