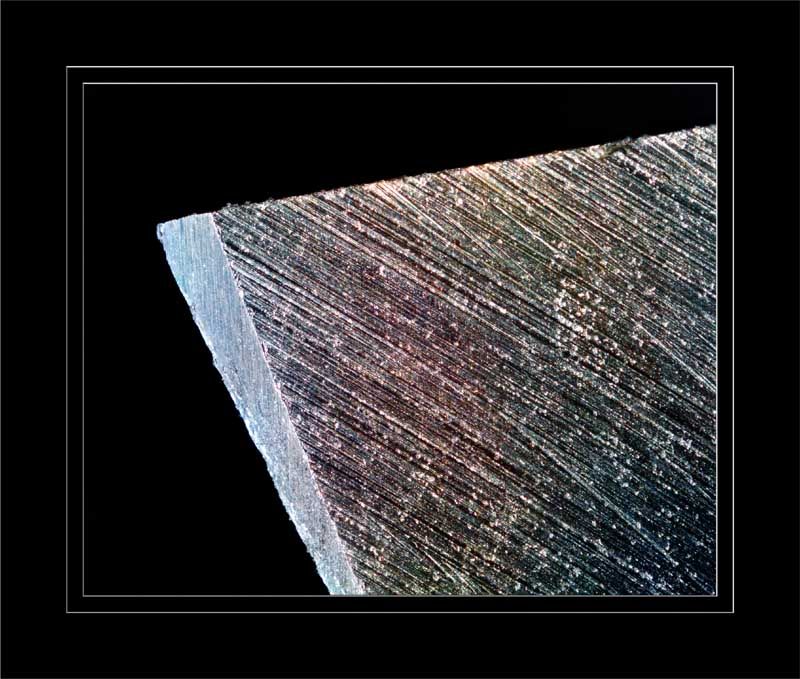

Top view:

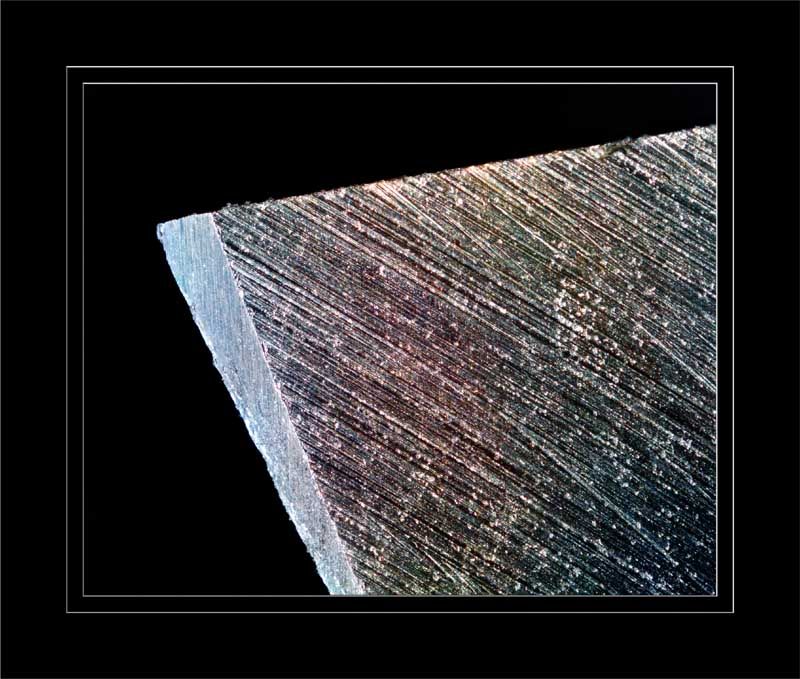

Left view or from the top right corner of the Top view image:

I was rather surprised by the amount of color in the last image. Both were just lighted with an Ott-Lite and saturation was increased in CS4.

Both were focus stacked with CS4.

Moderators: rjlittlefield, ChrisR, Chris S., Pau

Makes sense. Just be sure to check that you have things ground and aligned so you have enough front clearance that the foot of the tool doesn't drag. I've ruined more than one female thread by forgetting that detail.elf wrote:It should be able to cut both female and male threads on the adaptor. The female side will be 52mm and the tool axis will be at 30 degrees, so it should fit.

That colouration reminds me of the effects of anodizing!mgoodm3 wrote:coins turn color too, but you shouldn't clean them.

http://coinimaging.com/coins/1886sdrev.jpg