The story here is that today I was called to another house to fix a piece of equipment that was mostly not working but could be made to work sometimes if the power plug was held "just so".

It turned out that the wall socket needed replacing, but more importantly, so did the power plug. Replaced both, problem fixed, great.

However, the power plug problem was odd enough to attract my attention, because one of its prongs was quite loose in the plug. So I sliced apart the plug to see what had gone wrong.

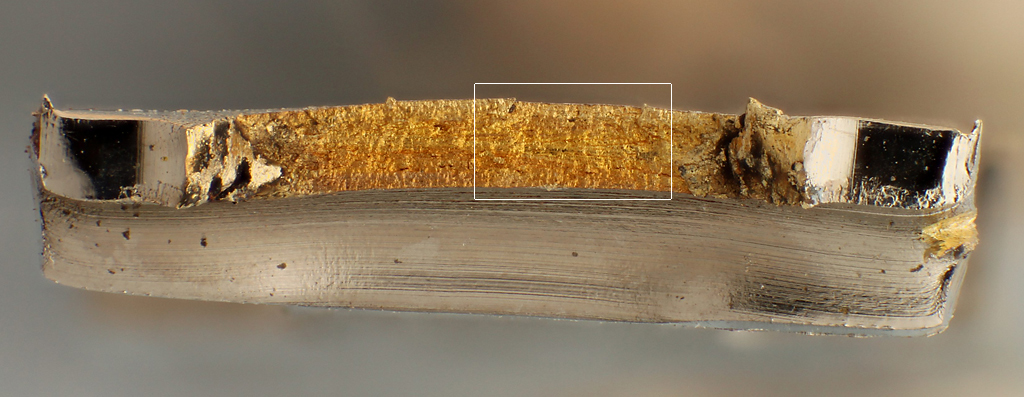

Here's what I found: that prong had been bent far enough and/or enough times that it had simply snapped.

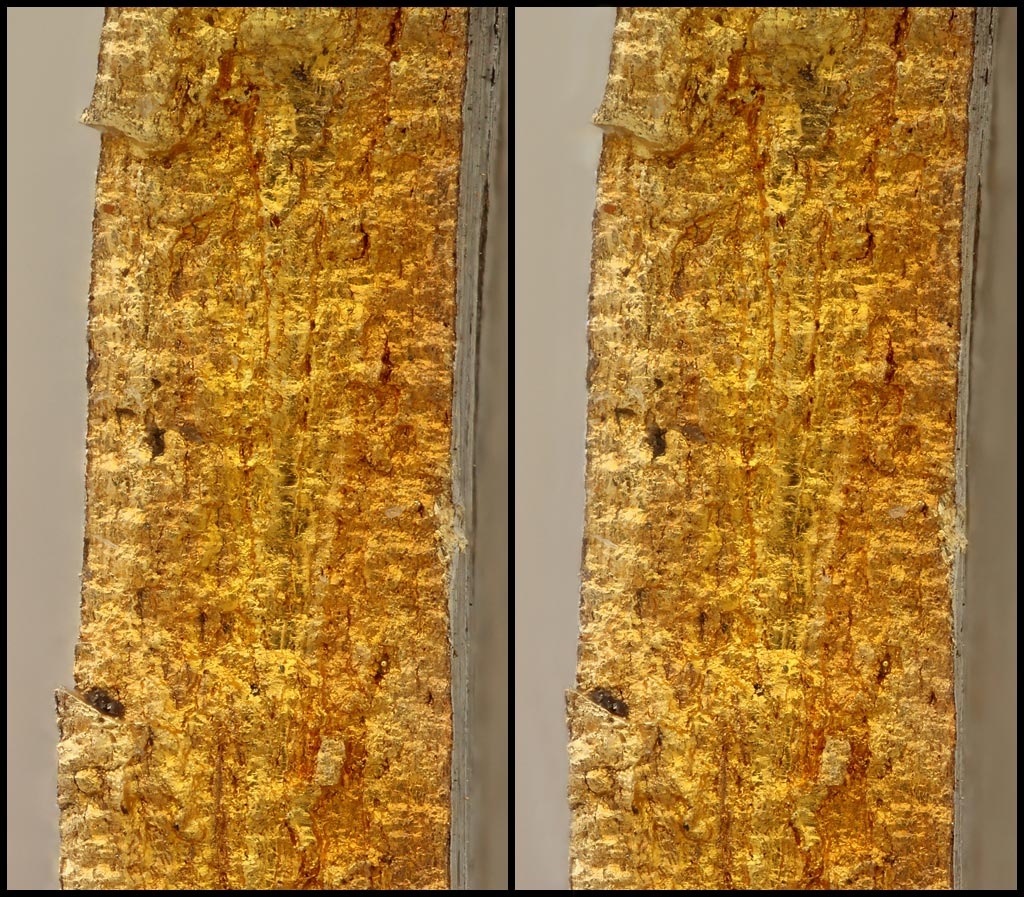

Here's the broken end of the prong, in its entirety. The stereo pair is the area outlined.

Again, I was surprised by the extent of visible layering in this piece of metal. Naively I would have expected it to be a lot more homogeneous. The cord and plug assembly superficially appeared to be high quality, but it seems that "under the covers", not so much.

I hope you find this as interesting as I did.

--Rik