The eight LEDs will still be clearly seen in the eyes of insects. Here an example of a partial stack:

The current version contains 8 LEDs each 3W. This was more than enough to use at ISO 200 an exposure times of 15 msec. Now I would like to make a new version. The light would be distributed internally through the walls. The LEDs can not go directly to the object. There are 2 difuse zones provided. The design is planned for the Mitutoyo lenses 10X and 5X. It can also be adapted for other lenses. Here the design:

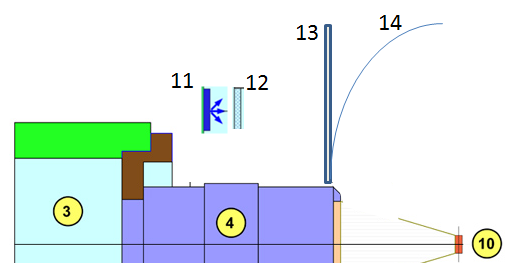

The different parts are as follows:

1 Powers leds 12 X -> problem is the right led choice.

2 Heat sink required for reduced power in continuous light live-view.

3 Tube lens, I use the AF ED 200 / F4 Nikkor macro.

4 Mitutoyo Plan Apo 10X Infinity Corrected Long WD Objective.

5. Inner ring light guide.

6 Outer ring light guide.

7 Outer snoot shape.

8 Inner snoot shape.

9. Diffuser 1 or 2 layers.

10. Object calculated for 5mm goes for 5X and 10X lenses.

11 Adapter Mitutoyo tube lens space minimal front tube lens and Mitutoyo lens.

Before I make the mechanical parts I would prefer to receive your opinions. Especially around the light channel and snoots with difuser is difficult. I can start with my existing power LEDs. In this new version I would use 12 leds. The outline is slightly larger than my existing version.

I think to use new LEDs. Newer LEDs have more power and better features. I do have problems with the selection. When I look at high CRI values, you have mostly lower color temperatures. I use RAW files, so the white ballans can be adapted. Those are 3000, 3500, 4000 and possibly even 5000 degrees. I definitely choose these individual components. You have the right characteristieken and you know what current you can use. On the camera I d'nt need a EFCS function, I control my own power LEDs. These are only turned on after the vibrations are gone. For this I use mirror-up mode and the LEDs only go on 400 msec after the shutter is fully open. So you have everything under control.

I wonder if it's important to use a max CRI value, I see versions of 90 and more. Higher CRI values ​​are generally a little more expensive but much difference. Anyway the price is not so important here. My current version had 6300 degrees and a CRI around 80 Because I like 9V LEDs, the choice is a little more limited. I always order leds directly to "Mouser", that choice is fixed. The control of the LEDs is in groups of 4 or 6. This way I can control the exposure direction.

Any proposal on the design is very welcome.

Frans.